- greenlineforms@yahoo.com

- (918)-894-2659

(785)-341-7934

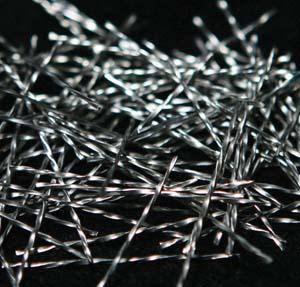

Helix Micro-Rebar

Helix can be used in most concrete applications including slab on grade, slab on metal deck, poured walls, ICF and precast products. Helix is being used in roads, grocery stores, airport terminals, hospitals, distribution centers, homes, storm shelters, military bases and more. Helix has been proven in areas at high risk for earthquakes and hurricanes as well as applications requiring blast resistance. Helix provides a 40% stronger concrete section able to absorb 200% more energy and can help achieve LEED goals. Helix eliminates placing errors, increases worksite safety, reduces construction time and reinforcing costs.

Helix works with the concrete to improve its performance. Helix increases the bending strength and raises the first crack strength. It also improves ductility, or flexibility, and adds considerable resistance to cracking. Helix is specifically designed to not affect the compressive strength of concrete.

Helix was originally designed to replace rebar for earthquake and blast resistance and has been used commercially for these and other structural applications.

During the finishing process, Helix settles below the surface leaving no visible pieces.

Helix is electrogalvanized with zinc to prevent rust and other corrosion. Unlike standard rebar which may not be treated at all or simply have a fragile epoxy coating, Helix has an infused layer of zinc that won’t chip, flake or crack.

Helix has been used in roads, grocery stores, airport terminals, hospitals, distribution centers, homes, storm shelters, military bases and more. Helix has been used in areas at high risk for earthquakes, TORNADOES, and hurricanes as well as applications requiring blast resistance.

Home | Products | Contractors & Architects | FAQ’s | Blog | About | Contact